Eliminatin of transverse deformation on the bars

Mechanical Engineering

In the production process of Impol PCP, we compress aluminum and its alloys in various geometric shapes (round, square, hexagonal, flat…) and profiles of various shapes at the request of the customer’s order.

Extrusion is also called rectilinear pressure extrusion, where the blank can be extruded in part or the whole can be pushed through an opening in the die or tool, where its cross-section and shape are reduced.

The advantage of extrusion is in the creation of very complex cross-sections and the possibility of extruding brittle materials. In the latter, shear and compressive stresses are encountered during the machining process, which allows deformation without tearing the material.

The extrusion process also allows the design of products with an excellent surface.

55 MN press is a direct press intended for direct pressing of rods and profiles made of aluminum and its alloys. Direct extrusion, also known as conventional extrusion, is the most widespread worldwide and is one of the main processing methods of aluminum.

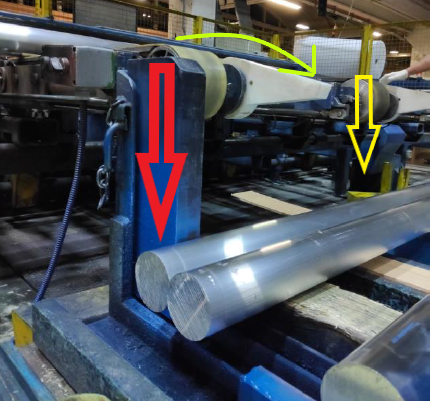

In this method of metalworking, the ball is inserted into the recipient after which the press piston begins to press through the die to the other side. The tool is considered to have a smaller cross-section than the round one. Compression conditions are given on work orders, tables, graphs, and parent technology.

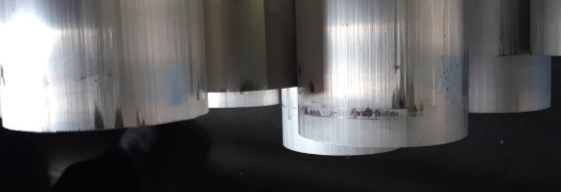

When extruding the rods, transverse deformations can occur due to the deviation of the alloying elements in the alloy or due to the incorrect speed of the main piston. The most common transverse deformations that occur are surface cracks, transverse scratches, joints, torn material, defects on the rods due to the extractor, and damage to the rods that occur during packaging.

In my dissertation, I will pay the most attention to the error called “stop marker on sticks”.

Stop marker or in working slang, joint appears on the rods in case of press errors. The joint is a transverse deformation on the rod that occurs when the press is stuck in the tool area, this rod is discarded and remelted.

One of the main goals of the diploma thesis will be to find out how to fix an error called a stop marker.