Cliché production on the location and optimization of the production process

Mechanical Engineering

The present diploma paper discusses the flexography printing method, which is among other things also used for printing covering the foil in the pharmaceutical industry, the implementation of a laser engraving machine into the GMP environment, as well as the optimization of purchasing, acceptance, and quality control of clichés, which are brought about by this implementation.

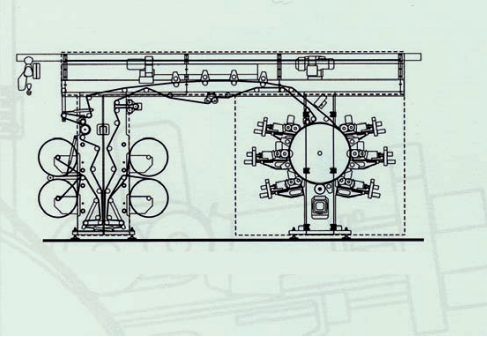

The flexo printing method is a technological process of direct rotation printing, where photopolymer clichés are used for printing. Printing elements on the clichés are shaped in full surfaces, lines, or rasterized dots. Their function is to transfer the printing paint onto the material to be printed. The vividness of color tones depends on the side corners of raster cones and on the printing pressure, which can influence the deformation of the raster cone.

The amount of color that is transferred onto the printing form depends on the raster cylinder, which is one of the key elements of a flexography printing machine. The raster cylinders can be produced in different ways. In the present times, photopolymer plates are used for the production of clichés for the flexo printing process. Analog copying or digital copying can be used for cliché production.

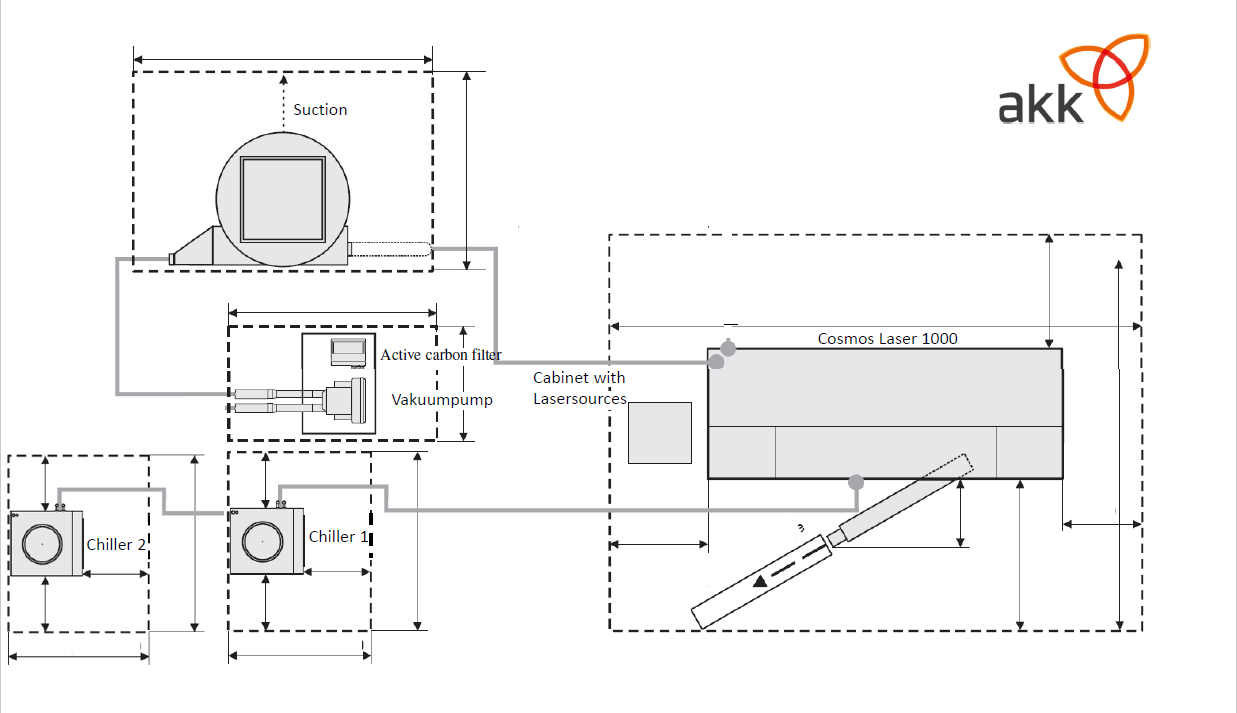

There are three construction designs of printing machines in the flexo printing process. These are rotational with the printing part in one column, rotational with consecutive printing parts, and rotational with a central printing part. Further, the diploma paper describes the activities which have to be carried out before the launching process. One of these is the URS specification which shows the basics of the system design and presents the user requirements that the system must have.

Another activity is also defining the system influence, where it is identified how the system influences the quality of the final product. Data integrity and patient safety are also identified, as well as supplier quality, which is a part of choosing the most suitable supplier.

This is followed by the launching process activities like the FAT and SAT testing, which ensure suitable configuration and running of the process (uncritical demands from the URS specifications are tested).

The last phase of the launching process is the qualification of the system. Next, the qualification plan is made, and the system qualification process is started, as well as the DQ, IQ, OQ, and PQ testing, which ensures a suitable system plan, its appropriate installation, and operation throughout the whole work process. These activities ensure an effective and repeatable work process. Further activities on this list are risk assessment, risk assessment of critical points, and completing the traceability matrix.

The final part of the paper discusses the influence of machine implementation on the environment, with regard to greenhouse gas emissions from cliché transportation. This assessment is based on the SIST EN 16258: 2013 standard.