Structural design with calculations and optimization of CNC machining of gearbox housing in shipbuilding

Mechanical Engineering

This thesis addresses the design, calculation, and optimization of CNC machining for the gearbox housing and its components. Gearboxes are key elements in the power transmission between main engines and propulsion systems in ships.

Special attention is given to the development of the housing and its internal components, which must ensure high strength, reliability, and resistance to corrosion, while also maintaining minimal weight, enabling cost-effective production, and facilitating easier product operation.

The thesis includes key design calculations, such as determining the mechanical properties of materials, load analysis, and the determination of required gearbox dimensions. Modern software packages for modeling, such as SolidWorks and AutoCAD, are used for this purpose. In addition to the design, significant emphasis is placed on the optimization of the CNC machining process. Various machining strategies, tool selection, and machine settings are explored, aiming to reduce machining time, lower costs, and improve surface quality.

Optimization takes into account the specific characteristics of the housing material, such as hardness, wear resistance, and weldability. The results of this work demonstrate how an optimized approach to design and machining can achieve a technically advanced, cost-effective, and durable gearbox solution tailored to the specific demands of the shipbuilding industry. The conclusions provide guidelines for further product development and improvements in manufacturing processes.

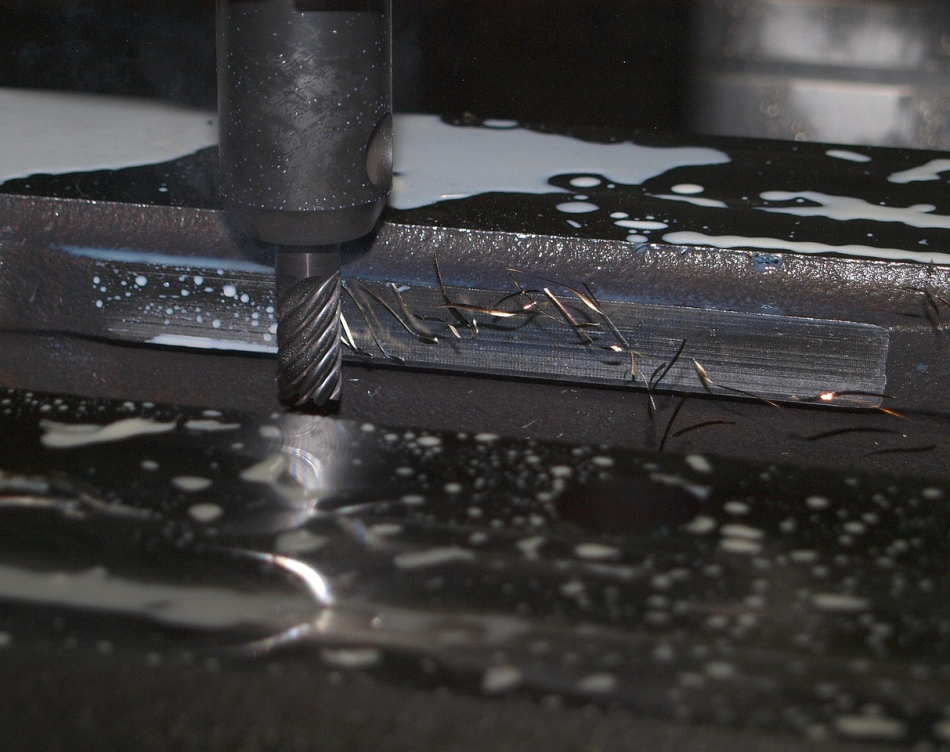

Various materials used in the production of gearbox housings in shipbuilding are analyzed, considering factors such as strength, corrosion resistance, and machinability. A comparison of materials is presented, focusing on their economic feasibility and suitability for industrial applications. Machining the gearbox housing requires the use of specific tools for precise cutting and shaping.

This section investigates different types of cutting tools and their optimization based on specific machining requirements, such as material type, shape, and size of the housing. Different machining processes, including cutting, drilling, grinding, and surface finishing, are examined, along with how to optimize these processes using modern CNC technologies.

The use of various machining strategies, such as progressive cutting, tool path optimization, and reducing machining time through increased automation and computer-aided planning, is also presented.